RAPID ROLL DOORS

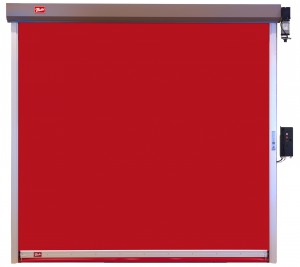

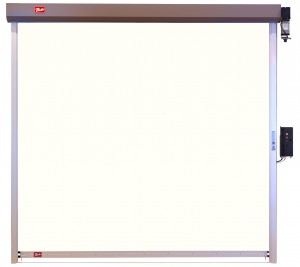

Inside buildings, between different departments, for example, there is sometimes a need for high-speed doors in order to maintain privacy, provide access for forklifts, etc. without the various work environments affecting each other. Our Revolid rapid roll door is the perfect solution for this. It has an opening speed of 1.8 m/s and its simple, reliable design makes it very affordable.

BENEFITS OF A RAPID ROLL DOOR FROM PRIDO

- Developed and manufactured in Sweden

- Endurance tested for 1 million opening cycles

- Entirely made to measure in sizes up to 3500 x 3500 mm

- 1.8 m/s opening speed

- Easy and quick to install thanks to few parts and screw fitting

- Requires minimal side and overhead space: 100 mm and 500 mm, respectively

- Motors and control units from Europe’s largest manufacturer, German GFA

- Light curtain in the opening for optimum safety and to reduce the risk of collisions

- Low maintenance costs

- Short delivery times and high delivery reliability

- CE-certified according to European standard on doors EN13241

- 7-year warranty within the Nordic countries, other countries 2-year warranty.

- 2-year warranty on electronics

SAFETY

Safety was an important consideration during the development process, and the doors are designed and CE-marked in accordance with the applicable standard for doors EN13241. The doors are equipped with a light curtain in the opening. When closing, it prevents contact with the door leaf and, at the same time, reduces the risk of collision damage. The door reverses to its fully open position as soon as anything breaches the light curtain zone.

Technical facts about Revolid rapid roll doors

CE-marking

All Revolid rapid roll doors are CE-marked to comply with the

Construction Products Regulation, Machinery Directive, Low Voltage Directive and EMC directive in accordance with the applicable EN 13241–1 standard.

Insulation rapid roll door

NPD (No Performance Determined, designed to be positioned indoors).

Air permeability

NPD, in accordance with EN EN 13241

Mechanical durability

The Revolid rapid roll door is designed and tested for 1,000,000 opening cycles in accordance with EN12605.

Resistance to water penetration

NPD, in accordance with EN12425.

Wind load resistance

NPD, in accordance with EN123444 and EN12424.

Door leaf

Scratch-resistant, fabric-reinforced PVC canvas, 900 g/m², approx. 0.9 mm thick. Available in 4 standard colors. HF-welded keder rails welded into place on the sides of the door canvas.

Windows

1.0 mm transparent PVC HF welded in the door leaf.

Bottom profile

Two-section aluminium beam with a structure that allows minor impacts without damage. The bottom profile also includes the weights that give the door fabric its spread out shape in the closed position.

Bottom skirt

70 mm-high bottom seal made from EPDM rubber ensures a good seal against the floor. The design of the base seal, base bar and door canvas also provides a solution that seals all the way out to the corners of the door (which is otherwise a common source of issues with high-speed doors), and neither are there any expensive components that might be easily damaged upon impact.

Personal safety is ensured via the light curtain in the sides of the door

Side profiles

Strong extruded aluminium profiles, in a two-section design that automatically creates cable ducts for the different door controls and motor connections, also function as the controls for the door leaf.

Seals

The canvas is sealed in narrow grooves in the side profiles. Aluminum profile to reduce the opening between the canvas and the wall above the door.

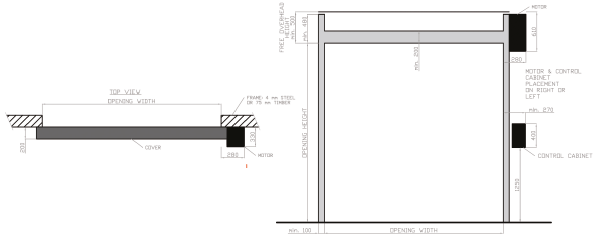

Fabric partition

Made from steel with a minimum thickness of 4 mm, or from wood with a minimum thickness of 75 mm.

Fabric controls

Heavy-duty, zinc-plated, 5 mm-thick laser-cut plates with elongated holes for easy installation and adjustment. Heavy-duty ball bearings bolted to the bearing brackets.

Door surround

Steel with minimum 3 mm thickness.Use thread profile steel screws for mounting.

Motor

GFA SI3,5.160 with an output speed of 160 rpm, which gives an opening and closing speed of 1.15 m/s, Operating voltage 3-phase 400V, operating current 1.1 A, frequency 50Hz, enclosure class IP54. Built-in brake/fall arrest device as fall protection. An alternative option is an induction motor with soft start and soft stop, giving an opening speed of 1 m/s and a closing speed of 0.5 m/s. Temperature range -10 to +40 degrees.

Control

GFA FI 4.250 frequency-controlled, single-phase, 230 V, IP65-rated motor available as an option. Built-in brake/catching device to provide fall protection. Temperature range -10 to +40°C.

Light curtain

Enclosed in aluminium and screwed to the side profile. 32 light beams, 15 m wiring on both transmitter and receiver, LED status indicator.

7-year warranty within the Nordic countries, other countries 2-year warranty.

See separate documentation with our warranty conditions.

Maintenance, servicing

The lowest service requirements in the market.

Once every 18 months or max. 50,000 openings.

Colour chart Revolid rapid roll door

The colour of an industrial door is obviously of great importance to the overall impression of the building. This is why Prido offers a number of standard colours for its rapid roll doors.

|

|

|

|

|---|---|---|---|

| RAL 3002 | RAL 9016 | RAL 5010 | RAL 7037 |

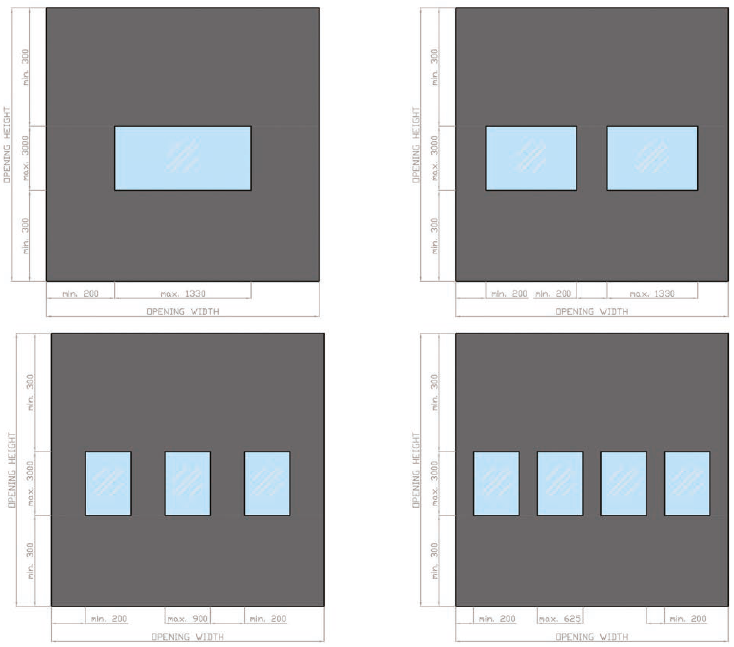

View window options for Revolid rapid roll door

1.0 mm clear PVC HF-welded into the door canvas

Door surround

Motors and controls

Motors and controls for Revolid doors are supplied by the German company GFA, Europe’s largest and leading manufacturer of

door drive and control equipment. The solution offers a range of different options and is also characterised by its operational reliability

and ease of use.

The following features are standard:

- Motor that opens and closes the door at 1.15 m/s

- Complete plug-in wiring between the engine and control

- Five-pole CEE plug for mains connection with plug-in connection in the control cabinet

- Control cabinet GFA TS971, IP65 classified

- Integrated three-button set; open, stop, close

- Digital limit settings

- Digital setting of rotational direction (used for phase inversion)

- Integrated radio receiver (only a remote control is needed for radio control)

- Two potential-free relay contacts

- Function for half opening

- Automatic time delay closure

- Power monitoring (prevents a person being lifted and transported by the door)

- Programmable maintenance cycle counter (including countdown, warning and stop function)

- Cycle counter for the total number of door openings

Fault memory and memory for programming change.

Light curtain for personal safety, which screens the door up to a height of 2.5 m

In addition to these functions, the control has also been prepared for the following connections:

- Active anti-crushing protection strip (not required when the door is equipped with a light curtain)

- The anti-crushing protection strip is either connected via a spiral cable or radio transmission

- Additional emergency stop

- Extra push button box or key operated switch

- Extra photocell

- External radio receiver

- Drawstring switch

- Extra collision detector

The control can also handle a variety of other external equipment such as code lock, card reader, radar and ground loops. If you want to connect several doors in a series, select a control box with the designation TS981. The Revolid door can then be functionally connected with other door models that use the same control.

Radiomottagare med fjärrkontroll

Radar

Tryckknappslåda och nyckelmanöverlåda

Kodlås och kortläsare

Dragsnöresöppning

Markslinga

Environmental Product Declaration – Ecolid folding door

Description of the company and product

The company:

Prido is, with more than 45 years of experience, one of the leading players in its industry.

The company works with design, development, manufacturing and marketing of industrial door solutions for industries and other door users in the Nordic region and Northern Europe.

Our objective is to offer the most attractive range in the industry that is best-adapted to the market.

Head office

Person responsible:

VD Josephine Stjärnerfält, 0512-295 88

josephine@prido.se

Contact person:

Environmental Coordinator Otto Claéson, 0512-295 85

otto.claeson@prido.se

Environmental work:

The company’s environmental policy is available on its website. Regular monitoring is carried out.

The product:

The Ecolid door is a folding door in a process laminated sandwich construction. The framework consists of aluminium profiles with steel reinforcement. The frame is filled with isocyanate and polyol that create a polyurethane insulation. Interior and exterior in hot galvanised sheet steel. Manufacturing takes place at the head office in Tråvad outside Vara. The service life of the door is estimated to be at least 25 years. The specified service life assumes that the product is used under the intended operating conditions. Heavy damage to the paint coating, which also damages the underlying galvanised layer should be repaired. Otherwise, maintenance is only required in accordance with the maintenance instructions in the user manual for the industrial door.

Declaration of contents:

The table below provides information on the composition of Ecolid. Door dimensions are customised to the customer’s requirements, so size varies.

The table shows the contents of the most common version – 4,000 mm x 4,000 mm, with a row of windows and pass door:

| Material | Amount |

| Steel | 233,2 kg |

| Aluminium | 65 kg |

| Rubber | 19,9 kg |

| Plastic | 0,1 kg |

| Polyurethane | 43 kg |

| Windows | 7,2 kg |

| Other | 0,2 kg |

| Totalt | 368,6 kg |

For more information about the constituent components, please contact the manufacturer.

Environmental Performance Declaration:

The information about the product’s environmental performance is divided into a section on manufacturing and a section on use.

Manufacturing:

The use of resources:

– Power Consumption approx. 104 kWh/door.

Pollutant emissions:

– No measurable emissions occur.

Other information:

– Hazardous waste: Some waste occurs with the cleaning of polyol and isocyanate machines. This is dealt with by Stena Recycling destruction. An average of approximately 150 kg per year has accrued, compared to the 192 tonnes of raw material used in production.

– Other waste: Residual products in the form of cut-outs occur in production. They are not classified as hazardous waste, and can be disposed of without restrictions and used for ground insulation.

– Chemicals used in production: Polyol, Isocyanate, hot melt adhesive.

Packaging:

– Packaging is done around a frame. The frame consists of steel side end pieces with wooden feet, wooden slats as spacers and plastic sheet on the bottom of the door packaging. Tied with plastic ties and wooden slats on top of the door frame. Loose accessories are packed in cardboard boxes.

Own emissions:

– None known.

Recycling:

The metal can be recycled. Wood and rubber remnants can be used in energy recovery. Cellular plastic waste can be disposed of without restrictions (not compostable). Glue residues can be burned/disposed of.