FOLDING DOORS

Some facilities require folding doors with a little extra class. Facilities where aspects such as design, function and economy are equally important to consider. As the name suggests, Ecolid truly is an economically sound and eco-friendly option, which also has a high-finish surface and minimal maintenance needs. So, if you need a well-insulated, affordable and stylish folding or hinged door, you don’t need to look any further.

BENEFITS OF A FOLDING DOOR FROM PRIDO

- Sweden’s best-selling folding door

- Developed and manufactured in Sweden

- Endurance tested for 1 million opening cycles

- Low maintenance costs

- Highest quality design and finish

- Short delivery times and high delivery reliability

- Approx. 40% higher U-value than frame-built folding doors

- Air permeability class 4, air leakage 1.8 m³/m² h according to EN12426

- Quick and easy to fit and remove

- Requires minimal space to the side and overhead

- 7-year warranty within the Nordic countries, other countries 2-year warranty.

- Highly effective rustproofing

- Risk of crushing completely eliminated

- CE-certified according to European standard on doors EN13241

- Entirely made to measure in many different designs

MANUAL OR MOTORIZED FOLDING DOOR?

Prido’s sales strategy is to deliver high quality at the right price. Unlike many other door manufacturers, we are completely uninterested in aftermarket services. Our goal is not to sell services but to deliver quality right from the start. The door in our range that best lives up to our strategy is the manual folding door. Why is that?

A manual folding door from Prido is a durable purchase. The folding door is designed to last a long time. The door is endurance tested for 1 million opening cycles. Properly installed, it is virtually indestructible. Durability doesn’t only mean a long service life. Our sandwich design also provides a U-value that is approximately 40% better than frame-built folding doors.

The folding door is operationally reliable. With all due respect to electronic and automatic doors, they don’t last forever and can also be vulnerable to external forces. A manual folding door basically never fails. Prido sells 14,000 doors a year and has 50 years of industry experience. Trust us, we know the difference between different types of industrial doors.

A manual folding door is easy to open and close, even when it’s 7 meters wide and 6 meters high, thanks to the smart design.

The cost of maintenance is extremely low. When investing in an industrial door, it’s important to consider the cost of maintenance, which is what it costs to own the door. For some door types, the purchase price is just a small part of the total cost. Many door manufacturers specify service intervals of 6-12 months, and each service can be costly. We dare say that our manual folding door is essentially maintenance free. In normal industrial environments, no maintenance is required. In environments where the doors get very dirty, washing may be required to maintain the rust protection. Care and maintenance do not require specialist expertise.

Folding doors are synonymous with a greatly reduced risk of collision injuries. The human field of view is larger horizontally than vertically. Vertically, the field of view can also be limited by the roof of a vehicle, for example. The sideways movement of a folding door means that the costly repairs of damage caused by collisions with bottom sections are virtually eliminated. In the unlikely event of an accident, it is exceptionally easy to replace a folding door leaf. Unlike a ceiling track door, for example, a door technician is not required to carry out the replacement.

The folding door is designed for quick and easy installation. A manual door can be installed by anyone who is handy, even without specialist knowledge. But if you would like help with the installation, Prido has qualified installers throughout Sweden. Thanks to its simplicity, the installation cost will be significantly lower than for other types of industrial doors.

The folding door fits in most door openings since it requires minimal space to the side and overhead, and it is available with either inward or outward opening.

MANUAL OR MOTORIZED FOLDING DOOR?

Prido’s sales strategy is to deliver high quality at the right price. Unlike many other door manufacturers, we are completely uninterested in aftermarket services. Our goal is not to sell services but to deliver quality right from the start. The door in our range that best lives up to our strategy is the manual folding door. Why is that?

En manuell vikport från Prido är ett hållbart köp. Vikporten är konstruerad för att hålla länge. Porten är långtidstestad för 1 miljon öppningscykler. Rätt monterad är den närmast outslitbar. Hållbarhet är inte bara livslängd. Vår sandwichkonstruktion ger också ett U-värde som är ca 40 % bättre än rambyggda vikportar.

Vikporten är driftsäker. Elektronik och automatik i all ära, men det håller inte för alltid och kan också vara känsligt för yttre påverkan. En manuell vikport krånglar i princip aldrig. Prido säljer 13.500 portar om året och har 50 års branscherfarenhet. Tro oss, vi vet skillnaden mellan olika typer av industriportar.

En manuell vikport är enkel att öppna och stänga, även när porten är 7 meter bred och 6 meter hög, tack vare en väl genomtänkt konstruktion.

Kostnaderna för underhåll är extremt låga. När man investerar i en industriport ska man vara uppmärksam på kostnaden för underhåll, dvs. vad det kostar att äga porten. Själva köpet är för vissa porttyper bara en liten del av den totala kostnaden. Många porttillverkare föreskriver 6-12 månaders serviceintervall och varje enskilt servicetillfälle kan bli kostsamt. Vi vågar påstå att vår manuella vikport i princip är underhållsfri. I normala industriella miljöer krävs inget underhåll. I starkt nedsmutsande miljöer kan det krävas tvättning för att bibehålla rostskyddet. All skötsel och underhåll klaras utan specialistkompetens.

Vikport är synonymt med kraftigt reducerad risk för påkörningsskador. Människans synfält är större horisontellt än vertikalt. Vertikalt kan dessutom synfältet begränsas av ex. taket på ett fordon. Vikportens sidogående rörelse gör att antalet påkörningsskador med kraschade bottensektioner och mycket dyra reparationer i det närmaste försvinner. Om olyckan mot förmodan ändå skulle vara framme, så är det oerhört enkelt att byta ett vikportsblad. Till skillnad från ex. en takskjutport krävs inte en porttekniker för att genomföra bytet.

Vikporten är konstruerad för ett enkelt och snabbt montage. En manuell port kan monteras av den händige, även utan specialistkunskaper. Men önskar man hjälp med montaget så har Prido välutbildade montörer i hela Sverige. Tack vare enkelheten blir montagekostnaden betydligt lägre än för andra typer av industriportar.

Vikporten passar i de flesta portöppningar tack vare att den erfordrar minimala sido- och överutrymmen och finns både för inåtgående- och utåtgående öppning.

Logistics centers

Manual folding doors that guarantee low operating costs

Industry

Sweden’s best-selling door for industrial environments

Service facilities

Motorized doors with high reliability and fast opening

Agriculture

Robust folding doors with top-class rustproofing

Logistics centers

Manual folding doors that guarantee low operating costs

Industry

Sweden’s best-selling door for industrial environments

Service facilities

Motorized doors with high reliability and fast opening

Agriculture

Robust folding doors with top-class rustproofing

MOTORIZED FOLDING DOORS

Motorized industrial doors have been around for a long time, but our PriDrive solution provides door owners with radically improved conditions. Motorized industrial doors have traditionally either been an expensive investment or costly to own, but are now becoming the best option for industrial doors.

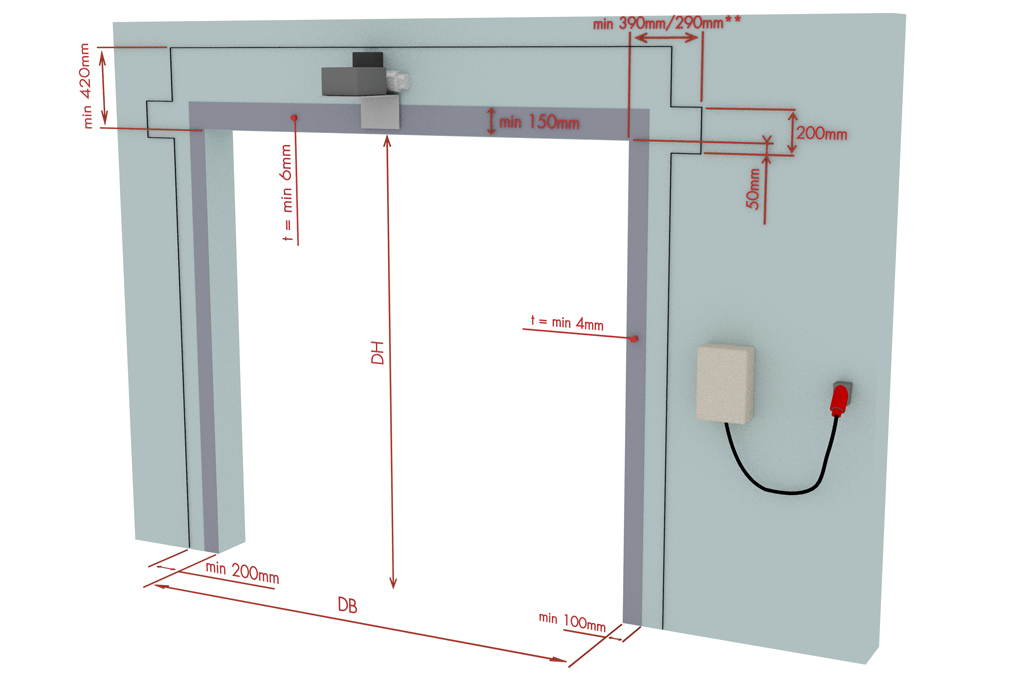

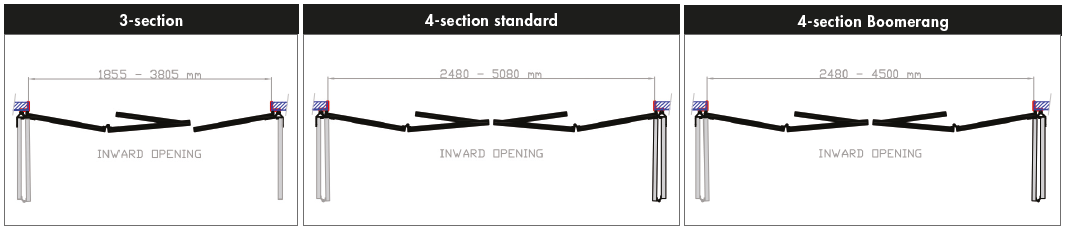

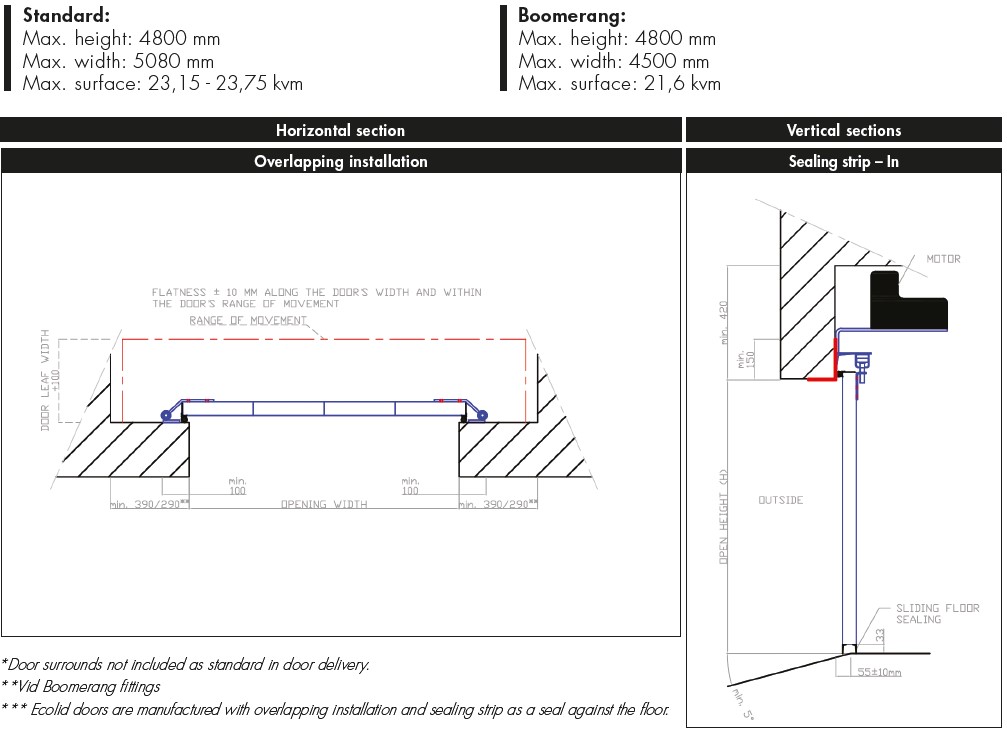

PriDrive Standard

A substantially lower investment cost compared to other folding door motors on the market. PriDrive Standard has an opening and closing time of approximately 11 seconds. It is available in 3-piece and 4-piece versions. On PriDrive, it is possible to disengage the drive unit directly from floor level for manual operation.

Max. width: 5040 mm

Max. height: 4800 mm

Max. opening: 23.15 – 23.75 m2

Min. side space: 390 mm

Min. overhead height: 420 mm

PriDrive Boomerang

The PriDrive with Boomerang fitting reduces the required side space to 290 mm and, at the same time, allows the motor to be disconnected directly from the floor level for manual operation. The Boomerang fitting is only available on 4-piece doors.

Max. width: 4500 mm

Max. height: 4800 mm

Max. opening: 21.6 m²

Min. side space: 290 mm

Min. overhead height: 420 mm

Technical specifications for Ecolid industrial doors, folding doors

CE marking Insulation properties Air permeability Mechanical durability Resistance to water penetration Wind load resistance Safety

Brackets mounted on the door leaves Windows Integrated pass door Pull handles for folding doors Insulation Frame hinges Lifting hinges (Optional) Central hinges Door leaves

Door surrounds Stable package Guide rails and brackets Safety Seals Door catch Cladding 7 year warranty Maintenance, servicing Lock

All Ecolid folding doors are CE-marked to comply with the Construction Products Regulation (CPR)

in accordance with the applicable standard EN13241-1.

Motor operated doors are also CE-marked

in accordance with the Machinery Directive, Low Voltage Directive

and EMC Directive.

U-value of 1.34 W/(m2/K) for a fully covered 5 x 5

m door or 1.47 W/(m2/K) with one glass row

type B1, calculated in accordance with EN12428.

Class 4, 1.8 m3/m2 h, in accordance with EN12426.

Designed and tested for 1.000.000 opening cycles in accordance with EN13241.

Class 3 in accordance with EN12425.

Class 2, 3, 4 or 5 depending on size.

Tested and classified in accordance with EN12444 and

EN12424.

Naturally, our motor operated doors meet

all relevant safety requirements and standards.

All crushing risks have been eliminated through the design

from the start and our doors can therefore be fully converted

into motor operation without any extra protection. Optical

anti-crushing protection is integrated in the door’s central seals

and additional safety photocells for positioning in the door opening are supplied as standard.

In addition to these features, there is a load monitor in the motor/control

for increased personal safety. Rubber strips

are designed to eliminate crushing risks between

door leaves and a door leaf/wall.

A minimum of three supporting brackets per leaf in order to prevent falls.

Electrogalvanized steel or aluminum. On outward-opening doors, the steel fittings are also powder-coated.

Argon gas-filled D4-12 insulated glass panes in six

different standard sizes. Standard breast height

about 1,070 mm. 7-year warranty within the Nordic countries, other countries 2-year warranty. against condensation between

the glass layers. Window frames in

natural anodised aluminium profiles with

broken thermal bridges.

Available in all variants.

Always outward opening. The position is governed by

the door option, see the planning guide.

Minimum door height allowing a pass door to be fitted

is 2,800 mm. The opening for

the pass door is governed by the width of the door leaves and

can be as narrow as 567 mm.

Minimum door leaf width with integrated pass door

is 770 mm. Dorma DL 919-50 lock housing.

Natural anodised aluminium handles.

50 mm freon-free polyurethane foam.

Multi-size adjustable steel hinges. Electrogalvanized on inward-opening doors and electrogalvanized and powder-coated on outward-opening doors.

Lubrication-free Teflon bushings. Screw into door surround.

Raises the door during the opening movement by 10

mm. Suitable for uneven floors. Good seal in

the closed position, and a soft and smooth opening movement

without undue wear on the sealing strip.

Natural anodised aluminium. Lubrication-free

Teflon bushings.

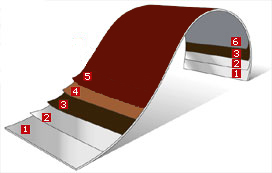

Process laminated sandwich panels.

Thickness 50 mm. Maximum size for individual door leaves is

1,250 x 6,000 mm. Frame for attaching

rubber strips etc. in natural anodised

aluminium profiles. Cast steel reinforcements

as attachment points for hinges,

guides, etc.

Steel, concrete or wood. At least 6 mm steel

for individual door leaves > 6 m2. Otherwise at least 3

mm steel when opening inwards and at least 4 mm when

opening outwards. Three different screw kits depending on the

type of surround.

Doors located in washing halls or stables require

a special component package that gives additional

corrosion protection in order for the warranties to apply.

Cannot be retrofitted.

Steel, hot galvanised and adjustable.

Screwed into the door surround.

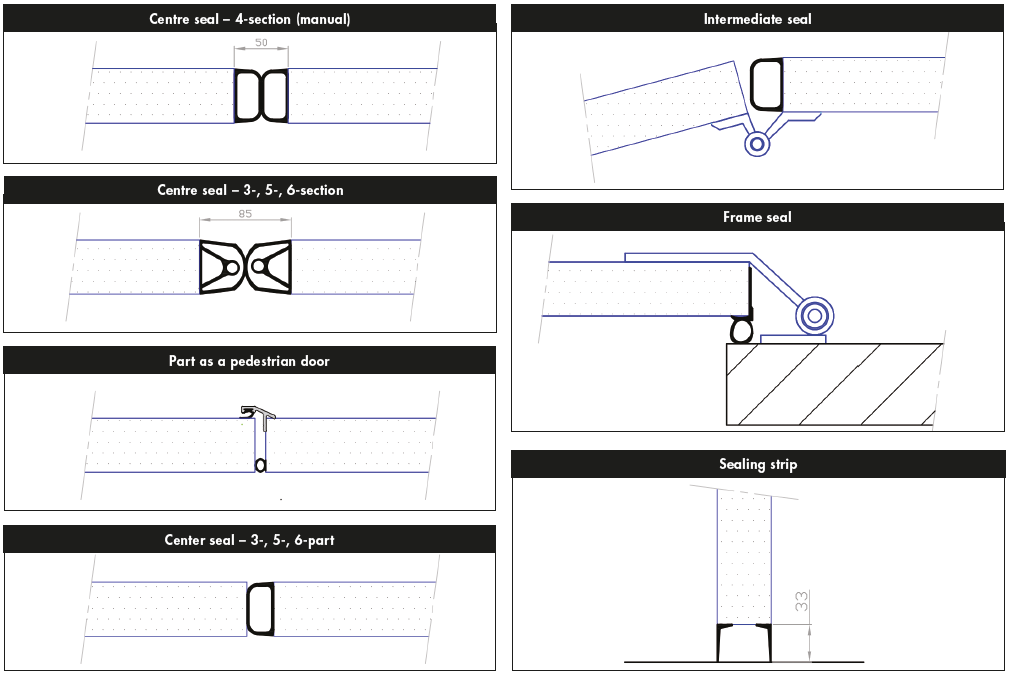

Rubber strips are designed to eliminate crushing risks between door leaves and a door leaf/wall. Optical anti-crushing protective strips on the closing edges of motor operated folding doors. All motor operated folding doors with an extra photocell on the folding side. At least three supporting brackets per folding door leaf in order to prevent falls.

Age resistant EPDM rubber.

The design meets the requirements of EN12453

without extra protection.

Automatic locking in the open position for both

inward and outward opening doors.

Interior and exterior of hot galvanised sheet steel.

Painted with 25 μm polyester paint.

See separate documentation with our

warranty conditions.

The lowest service requirements in the market.

Once every 18 months or a maximum of 25,000

openings for motor operated doors.

Garage bolts for inner padlocking as standard. If cylinder locking on the interior and exterior is preferred, Prido Fix 480 is available as optional extra.

Technical facts for Ecolid industrial doors, folding doors (motorized):

CE Marking Insulation value Air permeability Mechanical durability Water tightness Wind load capacity Safety

Brackets mounted on the door leaves Windows Recessed pedestrian door Middle hinge Frame hinge Door leaf Insulation Door surrounds Guide rails and brackets Seals Siding Size, PriDrive standard Size, PriDrive Boomerang

Warranty Maintenance, service Motor and gears Operating current Supply voltage Frequency Speed, outer axle Opening and closing speed Control unit Category according to EN13849-1 External fuse per phase Internal fuses – Motor Internal fuses – Control unit Energy consumption – Control unit Temperature range Protection class Intermittence

All folding doors are CE marked as per the Construction Products Regulation according to standard EN13241. Motorized doors are also CE-marked in accordance with the Machinery Directive, the Low Voltage Directive, and the EMC Directive.

U-value 1.57 W/(m2/K) on a fully covered 4×4 m

Folding door or 1.77 W/(m2/K) with 1 single-glazed type B1, calculated according to EN12428.

Class 4, 1.8 m3/m2 h, according to EN12426.

Configured and tested for 1.000.000 opening cycles according to EN13241.

Rating 3 as per EN12425

Classes 2, 3, 4 or 5 depending on size.

Tested and rated according to EN12444 and EN12424.

Our motorized folding doors naturally comply with all applicable safety requirements and standards. All risk of crushing eliminated in the design from the start. Optical crush protection built into the door’s center seals and additional safety photoresistor for placement in the door opening as standard. In addition to these functions, the motor/control unit contains a load monitor for personal protection. Rubber strips designed to eliminate the risk of crushing between door leaf and door leaf, and door leaf and wall. At least 3 load-bearing brackets per leaf to prevent falls.

Made of steel, galvanized.

Argon-filled D4-12 insulated-glass panes in six different standard sizes. Standard chest height approx. 1,070 mm. Seven-year warranty against condensation between glass panes. Window frames made from natural anodized aluminum profiles with thermal breaks.

Can be provided for all variants. Naturanodiserad aluminium. Smörjfria teflonbussningar. Always outward opening. Placement is contingent on the door, refer to Project Planning Guide. A minimum door height of 2,800 mm is required to fit a pedestrian door. The pedestrian door aperture is contingent on the door leaf width and can be as small as 567 mm. Min. door leaf width with recessed pedestrian door is 770 mm. Dorma Lock Housing DL 919-50.

Natural anodized aluminum. Lubrication-free Teflon bushings.

Steel, electrogalvanized, multi-size adjustable. Screw into door surround.

Process-laminated sandwich panels. 50 mm thickness. Frame for fitting rubber seals, etc. Made of natural anodized aluminum profiles. Cast steel reinforcements as attachment points for hinges, controls, etc.

50 mm freon-free polyurethane cellular plastic.

Made of steel, crossbars min. 6 mm thick, side legs min. 4 mm thick.

Made of steel, hot-dip galvanized and adjustable. Screw into door surround.

Made of age-resistant EPDM rubber. The design meets the requirements of EN12453 without extra protection.

Interior and exterior in hot-dip galvanized sheet metal. Coated with 25 µm polyester paint.

Max. width: 5040 mm, max. height: 4800 mm

Max. opening: 23.15–23.75 m² (depending ondesign).

Max. width: 4500 mm, max. height: 4800 mm

Max. opening: 21.6 m²

7-year warranty within the Nordic countries, other countries 2-year warranty. on folding doors and mechanical components. 2-year warranty on electronics. Refer to separate document detailing our warranty conditions.

The lowest service requirements in the market. Once/18 months or max. 30,000 openings.

Prido PriDrive

1,10 A

3x400V+N+PE

50 Hz

Approx. 2.0 RPM

Standard: approx. 11 s w/4-leaf, approx. 10 s w/3-leaf

Boomerang: approx. 13 s

Prido PriDrive

Pl”c” category 3

10-16 A

3×2.5A slow blow 5×20 mm, breaking capacity 1500A

1x1A slow blow 5×20 mm

5 W

From -10 to +40°C

IP65

Continuously, max. 1 complete cycle / min

Colour shades, colours for Ecolid industrial doors and folding doors

The colour of an industrial door is obviously of great importance to the overall impression of the building.

All Ecolid industrial doors are clad in sheet steel

SILVER 045

RAL: 9006

GREEN 874

RAL: 6003

LIGHT GREY 022

RAL: 7044

BLUE 558

RAL: 5009

DARK GREY 036

RAL: 7024

WHITE 010

RAL: 9010

RED 758

RAL: 3009

ANTRACIT GREY 035

RAL: 7016

GRAPHITE 044

RAL: 9007

BROWN 434

RAL: 8017

BLACK 015

RAL: 9005

Please note that the actual colour may vary from what is shown on a computer display. For the exact colours, contact us for sheet samples.

Colour composition

- Sheet steel

- Zinc layer

- Passivation layer

- Primer

- Painted with 25 μm polyester paint

- Colour on rear side 10 µm

Project guidelines Ecolid folding door, industrial door.

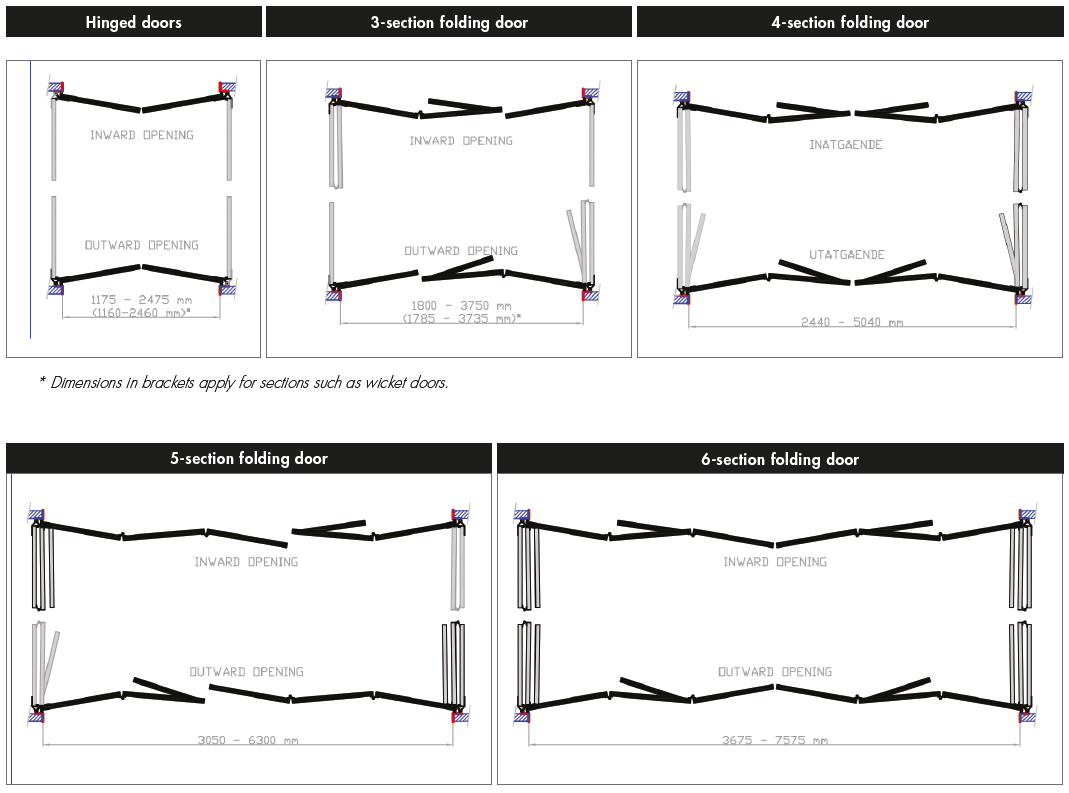

Opening options

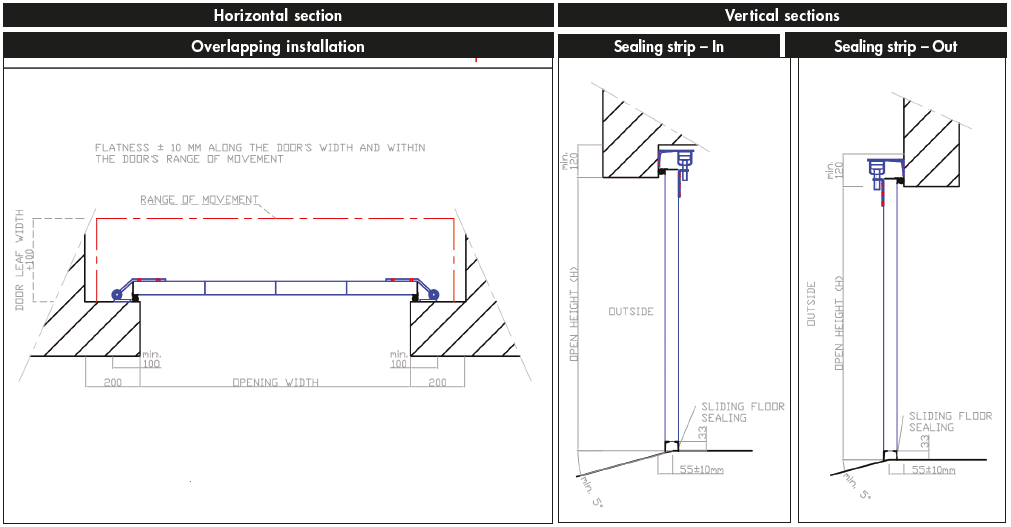

Mounting and connections in the door opening

Ecolid doors are manufactured with overlapping installation and sealing strip as a seal against the floor.

Max height = 6,005 mm (4,600)

Sections such as pass doors = 3,200 mm

(Dimensions in brackets apply with hinged doors.)

Overlapping installation for folding doors

Seals for hinged doors and folding doors

Projekteringsvägledning Ecolid motordriven vikport (PriDrive), industriport.

Öppningsalternativ:

Inbyggnadsmått

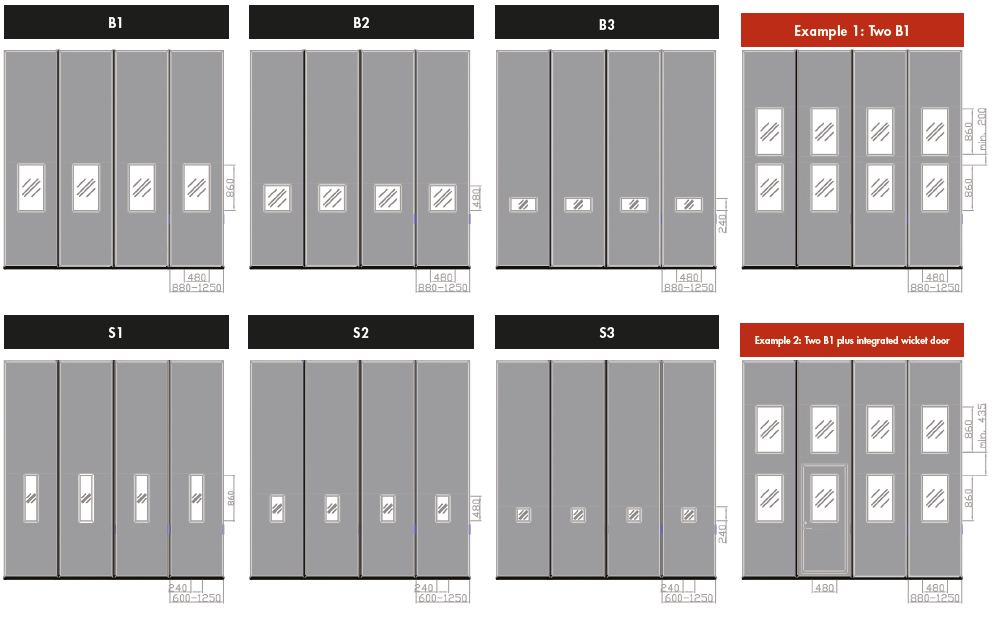

Windows Folding doors, industrial doors

Ecolid folding doors can be fitted with double-glazed, insulated windows. You can choose between six different window types in our standard range, but special sizes are also available on request. The position and number are optional, on the condition that they fit within the dimensions listed below. Standard breast height = 1,070 mm.

Environmental Product Declaration – Ecolid folding door

Description of the company and product

The company:

Prido is, with more than 45 years of experience, one of the leading players in its industry.

The company works with design, development, manufacturing and marketing of industrial door solutions for industries and other door users in the Nordic region and Northern Europe.

Our objective is to offer the most attractive range in the industry that is best-adapted to the market.

Head office

Person responsible:

VD Josephine Stjärnerfält, 0512-295 88

josephine@prido.se

Contact person:

Environmental Coordinator Otto Claéson, 0512-295 85

otto.claeson@prido.se

Environmental work:

The company’s environmental policy is available on its website. Regular monitoring is carried out.

The product:

The Ecolid door is a folding door in a process laminated sandwich construction. The framework consists of aluminium profiles with steel reinforcement. The frame is filled with isocyanate and polyol that create a polyurethane insulation. Interior and exterior in hot galvanised sheet steel. Manufacturing takes place at the head office in Tråvad outside Vara. The service life of the door is estimated to be at least 25 years. The specified service life assumes that the product is used under the intended operating conditions. Heavy damage to the paint coating, which also damages the underlying galvanised layer should be repaired. Otherwise, maintenance is only required in accordance with the maintenance instructions in the user manual for the industrial door.

Declaration of contents:

The table below provides information on the composition of Ecolid. Door dimensions are customised to the customer’s requirements, so size varies.

The table shows the contents of the most common version – 4,000 mm x 4,000 mm, with a row of windows and pass door:

| Material | Amount |

| Steel | 233,2 kg |

| Aluminium | 65 kg |

| Rubber | 19,9 kg |

| Plastic | 0,1 kg |

| Polyurethane | 43 kg |

| Windows | 7,2 kg |

| Other | 0,2 kg |

| Totalt | 368,6 kg |

For more information about the constituent components, please contact the manufacturer.

Environmental Performance Declaration:

The information about the product’s environmental performance is divided into a section on manufacturing and a section on use.

Manufacturing:

The use of resources:

– Power Consumption approx. 104 kWh/door.

Pollutant emissions:

– No measurable emissions occur.

Other information:

– Hazardous waste: Some waste occurs with the cleaning of polyol and isocyanate machines. This is dealt with by Stena Recycling destruction. An average of approximately 150 kg per year has accrued, compared to the 192 tonnes of raw material used in production.

– Other waste: Residual products in the form of cut-outs occur in production. They are not classified as hazardous waste, and can be disposed of without restrictions and used for ground insulation.

– Chemicals used in production: Polyol, Isocyanate, hot melt adhesive.

Packaging:

– Packaging is done around a frame. The frame consists of steel side end pieces with wooden feet, wooden slats as spacers and plastic sheet on the bottom of the door packaging. Tied with plastic ties and wooden slats on top of the door frame. Loose accessories are packed in cardboard boxes.

Own emissions:

– None known.

Recycling:

The metal can be recycled. Wood and rubber remnants can be used in energy recovery. Cellular plastic waste can be disposed of without restrictions (not compostable). Glue residues can be burned/disposed of.